Elasticity!

Could anyone explain me that why we'll subtract the area(found from max force) from the area before stress is applied?

I thought using Stress = Force/Area would give the answer.

Max Stress = 9.5x108 Pa

Force = 1.9x103 N.

So max area of wire when max stress is being applied = 2x10-6

Shouldn't this above (calculated) area be the max area of cross section of the sphere?

This is what mark scheme says:

CIE, am I right? I remember this question.

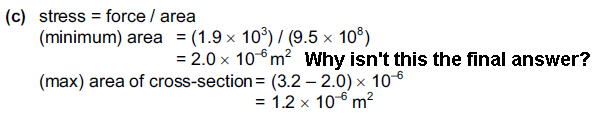

Pay attention to what the question says "calculate the maximum are of cross-section of the bubble...". They don't want you to find the area of cross-section of the rod...They want you to find the area of cross-section of the bubble. For that you will have to subtract the initial and final areas of cross-sections of the rod.

CIE tends to be sneaky just like that! Read the question carefully! Can't stress on that enough!

Pay attention to what the question says "calculate the maximum are of cross-section of the bubble...". They don't want you to find the area of cross-section of the rod...They want you to find the area of cross-section of the bubble. For that you will have to subtract the initial and final areas of cross-sections of the rod.

CIE tends to be sneaky just like that! Read the question carefully! Can't stress on that enough!

(edited 13 years ago)

Original post by aura1947

CIE, am I right? I remember this question.

Pay attention to what the question says "calculate the maximum are of cross-section of the bubble...". They don't want you to find the area of cross-section of the rod...They want you to find the area of cross-section of the bubble. For that you will have to subtract the initial and final areas of cross-sections of the rod.

CIE tends to be sneaky just like that! Read the question carefully! Can't stress on that enough!

Pay attention to what the question says "calculate the maximum are of cross-section of the bubble...". They don't want you to find the area of cross-section of the rod...They want you to find the area of cross-section of the bubble. For that you will have to subtract the initial and final areas of cross-sections of the rod.

CIE tends to be sneaky just like that! Read the question carefully! Can't stress on that enough!

Yep, it is CIE.

I think I've read it carefully but won't the area of cross section of bubble be equal to the area of the rod at the max stress? And according to the diagram it seems that bubble is situated in mid of the rod and when the rod will be stretched fully its area will come close to the area of the bubble?

Original post by Zishi

Yep, it is CIE.

I think I've read it carefully but won't the area of cross section of bubble be equal to the area of the rod at the max stress? And according to the diagram it seems that bubble is situated in mid of the rod and when the rod will be stretched fully its area will come close to the area of the bubble?

I think I've read it carefully but won't the area of cross section of bubble be equal to the area of the rod at the max stress? And according to the diagram it seems that bubble is situated in mid of the rod and when the rod will be stretched fully its area will come close to the area of the bubble?

No, why would you assume that?

At maximum tensile stress, the rod will break...It doesn't imply that the area of cross-section of the bubble will equal that of the rod.

Hope that helped.

Original post by aura1947

No, why would you assume that?

At maximum tensile stress, the rod will break...It doesn't imply that the area of cross-section of the bubble will equal that of the rod.

Hope that helped.

At maximum tensile stress, the rod will break...It doesn't imply that the area of cross-section of the bubble will equal that of the rod.

Hope that helped.

Sorry but as the mark scheme did, it subtracted the area of rod at max stress from the original area of the rod. Won't that result represent the change in area of the rod?

So how can change in area of the rod represent the area of cross section of the bubble?

Original post by Zishi

Sorry but as the mark scheme did, it subtracted the area of rod at max stress from the original area of the rod. Won't that result represent the change in area of the rod?

So how can change in area of the rod represent the area of cross section of the bubble?

So how can change in area of the rod represent the area of cross section of the bubble?

Look at it this way:

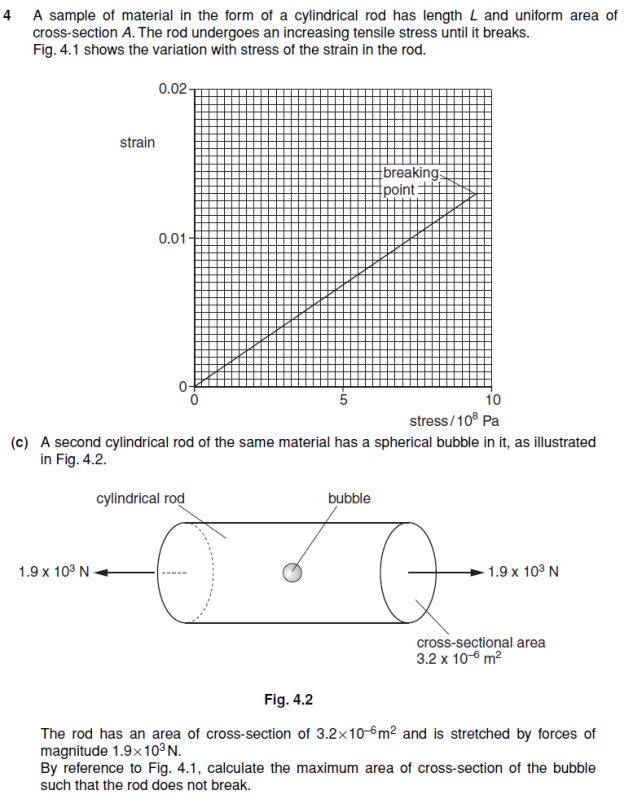

From the graph we know that the maximum stress this material can take (the breaking stress) is 9.6 x 108Pa

Now for the rod we have the data for, we know the force is 1.9x103N

Let's look at what cross section area we could go down to before it breaks

Using Breaking stress = F/A then A= force / breaking stress

This gives a possible minimum area of 2 x 10-6 m2

Less than this and the rod will break.

The rod we have has a cross section of 3.2x10-6 m2

so, ignoring the bubble for the moment, it is well within the limit.

In fact, it is 1.2x10-6 m2 inside the limit.

As you increase the size of the bubble from nothing, you are reducing the effective cross section by an amount equal to the cross section area of the bubble.

So this means that I can increase the bubble up to 1.2 x 10-6 m2 before the rod will break.

At this point, the 3.2 x 10-6 area would be made up of 2x 10-6 of metal and 1.2 x 10-6 of bubble. (of nothing in other words).

It's only the metal that holds the rod together, so if the bubble gets bigger than this, there will be insufficient material to hold it together, stress will be above the breaking limit, and it will break.

Original post by Stonebridge

Look at it this way:

From the graph we know that the maximum stress this material can take (the breaking stress) is 9.6 x 108Pa

Now for the rod we have the data for, we know the force is 1.9x103N

Let's look at what cross section area we could go down to before it breaks

Using Breaking stress = F/A then A= force / breaking stress

This gives a possible minimum area of 2 x 10-6 m2

Less than this and the rod will break.

The rod we have has a cross section of 3.2x10-6 m2

so, ignoring the bubble for the moment, it is well within the limit.

In fact, it is 1.2x10-6 m2 inside the limit.

As you increase the size of the bubble from nothing, you are reducing the effective cross section by an amount equal to the cross section area of the bubble.

So this means that I can increase the bubble up to 1.2 x 10-6 m2 before the rod will break.

At this point, the 3.2 x 10-6 area would be made up of 2x 10-6 of metal and 1.2 x 10-6 of bubble. (of nothing in other words).

It's only the metal that holds the rod together, so if the bubble gets bigger than this, there will be insufficient material to hold it together, stress will be above the breaking limit, and it will break.

From the graph we know that the maximum stress this material can take (the breaking stress) is 9.6 x 108Pa

Now for the rod we have the data for, we know the force is 1.9x103N

Let's look at what cross section area we could go down to before it breaks

Using Breaking stress = F/A then A= force / breaking stress

This gives a possible minimum area of 2 x 10-6 m2

Less than this and the rod will break.

The rod we have has a cross section of 3.2x10-6 m2

so, ignoring the bubble for the moment, it is well within the limit.

In fact, it is 1.2x10-6 m2 inside the limit.

As you increase the size of the bubble from nothing, you are reducing the effective cross section by an amount equal to the cross section area of the bubble.

So this means that I can increase the bubble up to 1.2 x 10-6 m2 before the rod will break.

At this point, the 3.2 x 10-6 area would be made up of 2x 10-6 of metal and 1.2 x 10-6 of bubble. (of nothing in other words).

It's only the metal that holds the rod together, so if the bubble gets bigger than this, there will be insufficient material to hold it together, stress will be above the breaking limit, and it will break.

Oh, wow. I thought a lot on this and I think I get it now.

What I get is that when we apply the max stress on the rod we use up all the 'empty' space to cause the extension and reduce its cross section area. And when it's at the max stress it has no 'empty' space for extension and it will break then. And that 'empty' space's area may be called as the max area of the cross section of the bubble, right?

Sorry if I misunderstood it.

I'll try to think more on your previous post if what I get is wrong.

I'll try to think more on your previous post if what I get is wrong.The bubble would be a weak point in the material and it would break there at the weakest point.

The reason is that the cross section area for the purpose of calculating the breaking stress is that of the metal. The cross section of the bubble is of no use. (It's full of air or nothing!)

So the rod's cross section (at the weak point) is made up of metal + bubble. It's only the metal that holds it together, and the value of the metal part of the cross section cannot go below 2 x 10-6, the breaking stress of the material.

So if you have a cross section of 3.2 x 10-6, of which only 2 x 10-6 is metal (and 1.2 x 10-6 is bubble), you are just on the limit of breaking. It's the metal that holds the rod together.

The cross section area of the bubble is not changing as you stretch the rod - I'm just using the idea of first considering what the case would be with no bubble, and then looking at what happens as you increase its size to 1.2 x 10-6. That value is the limiting size the bubble can be for the rod to still just hold together when the rod's size is 3.2x10-6

The reason is that the cross section area for the purpose of calculating the breaking stress is that of the metal. The cross section of the bubble is of no use. (It's full of air or nothing!)

So the rod's cross section (at the weak point) is made up of metal + bubble. It's only the metal that holds it together, and the value of the metal part of the cross section cannot go below 2 x 10-6, the breaking stress of the material.

So if you have a cross section of 3.2 x 10-6, of which only 2 x 10-6 is metal (and 1.2 x 10-6 is bubble), you are just on the limit of breaking. It's the metal that holds the rod together.

The cross section area of the bubble is not changing as you stretch the rod - I'm just using the idea of first considering what the case would be with no bubble, and then looking at what happens as you increase its size to 1.2 x 10-6. That value is the limiting size the bubble can be for the rod to still just hold together when the rod's size is 3.2x10-6

(edited 13 years ago)

Original post by Stonebridge

The bubble would be a weak point in the material and it would break there at the weakest point.

The reason is that the cross section area for the purpose of calculating the breaking stress is that of the metal. The cross section of the bubble is of no use. (It's full of air or nothing!)

So the rod's cross section (at the weak point) is made up of metal + bubble. It's only the metal that holds it together, and the value of the metal part of the cross section cannot go below 2 x 10-6 - the breaking stress of the material.

So if you have a cross section of 3.2 x 10-6, of which only 2 x 10-6 is metal (and 1.2 x 10-6 is bubble), you are just on the limit of breaking. It's the metal that holds the rod together.

The cross section area of the bubble is not changing as you stretch the rod - I'm just using the idea of first considering what the case would be with no bubble, and then looking at what happens as you increase its size to 1.2 x 10-6. That value is the limiting size the bubble can be for the rod to still just hold together when the rod's size is 3.2x10-6

The reason is that the cross section area for the purpose of calculating the breaking stress is that of the metal. The cross section of the bubble is of no use. (It's full of air or nothing!)

So the rod's cross section (at the weak point) is made up of metal + bubble. It's only the metal that holds it together, and the value of the metal part of the cross section cannot go below 2 x 10-6 - the breaking stress of the material.

So if you have a cross section of 3.2 x 10-6, of which only 2 x 10-6 is metal (and 1.2 x 10-6 is bubble), you are just on the limit of breaking. It's the metal that holds the rod together.

The cross section area of the bubble is not changing as you stretch the rod - I'm just using the idea of first considering what the case would be with no bubble, and then looking at what happens as you increase its size to 1.2 x 10-6. That value is the limiting size the bubble can be for the rod to still just hold together when the rod's size is 3.2x10-6

The third paragraph was pretty helpful. I may be repeating your words - 2 x 10-6 is actually the area of the 'material' which is embedded in the rod. And when area of rod is 3.2 x 10-6, it is the area of the empty space(which we can assume to be the max area of bubble) + area of that embedded 'material' in the rod.

PS. 'Material' may represent particles in the rod.

Thanks a lot for explaining it to me.

Yes. Area of the material (metal) plus area of bubble (air? nothing?) is equal to the total cross section area at that point. The area of the material part must be at least 2 x 10-6 to prevent breaking.

Original post by Stonebridge

Yes. Area of the material (metal) plus area of bubble (air? nothing?) is equal to the total cross section area at that point. The area of the material part must be at least 2 x 10-6 to prevent breaking.

Oh, alas! I get something now.

Feeling good.

Feeling good.Thanks again.

Original post by Stonebridge

Yes. Area of the material (metal) plus area of bubble (air? nothing?) is equal to the total cross section area at that point. The area of the material part must be at least 2 x 10-6 to prevent breaking.

Here's just another small part of the same question:

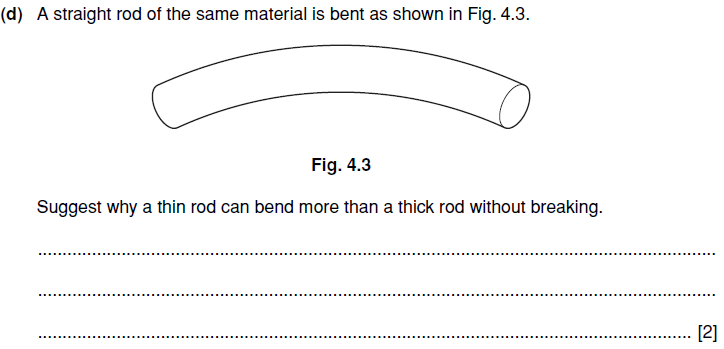

When you bend a rod, the atoms on the outside are stretched, and those on the inside are compressed.

If stretching (or compressing) is going to cause the rod to break, which is going to break first; a thick rod or a thin rod?

Original post by Stonebridge

When you bend a rod, the atoms on the outside are stretched, and those on the inside are compressed.

If stretching (or compressing) is going to cause the rod to break, which is going to break first; a thick rod or a thin rod?

When you bend a rod, the atoms on the outside are stretched, and those on the inside are compressed.

If stretching (or compressing) is going to cause the rod to break, which is going to break first; a thick rod or a thin rod?

I know that a thin rod will break first, plus I also know that one side will be stretched and the other one will be compressed.

But I don't understand why it will break first?

But I don't understand why it will break first?

EDIT: I think that stretching (or compressing) for thick rod will be less for the same force as applied on the thin one. And for causing the same extension of both more stress would have to be applied on thick rod and that stress may exceed the breaking point of the thick rod, so it may break first. But I don't think so that mark scheme accepts this statement.

(edited 13 years ago)

Quick Reply

Related discussions

- Maths Further ( Mechanics)

- A level further maths elastic spring and strings question

- Can an inferior good be income elastic?

- GCSE Physics help!

- Can an inferior good be income elastic? (A level business)

- FM2, Elastics and springs question

- How's FM1 - Edexcel?

- How Hard is A Level Further Maths?

- Further Mechanics Question

- Circular motion question help

- Elastic collisions (A level physics)

- Thermal Physics Help

- Further Mechanics 1 question (Elastic String and Springs)

- Exams motivation

- microeconomics evaluation help

- Edexcel GCSE Physics Paper 2 Higher Tier Triple 1PH0 2H - 16th June 2023 [Exam Chat]

- Economics A edexcel paper 1

- Economics Question

- Stuck on analysis of research

- IB Econ real world example

Latest

Last reply 10 minutes ago

Official University of Edinburgh Applicant Thread for 2024Last reply 13 minutes ago

Official UCL Offer Holders Thread for 2024 entryLast reply 19 minutes ago

Official University College London Applicant Thread for 2024Last reply 26 minutes ago

2023 ** Borders and Enforcement, Crime & Compliance - ICE - Immigration OfficersLast reply 37 minutes ago

Can I do economics degree without a level maths?Last reply 56 minutes ago

BAE systems degree apprenticeships September 2024Last reply 1 hour ago

Government Social Research Placement interview questionsLast reply 1 hour ago

Official University of St Andrews Applicant Thread for 2024Last reply 1 hour ago

Standard Chartered Apprenticeships 2024